This website uses cookies to enhance your browsing experience. By proceeding, you consent to our cookie usage. How We Use Cookies

It’s All Here.

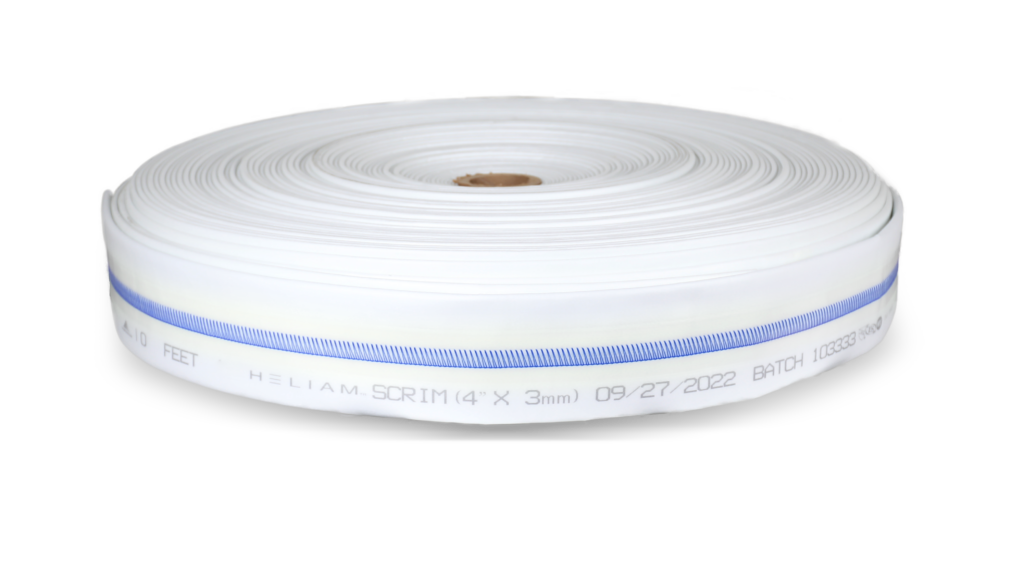

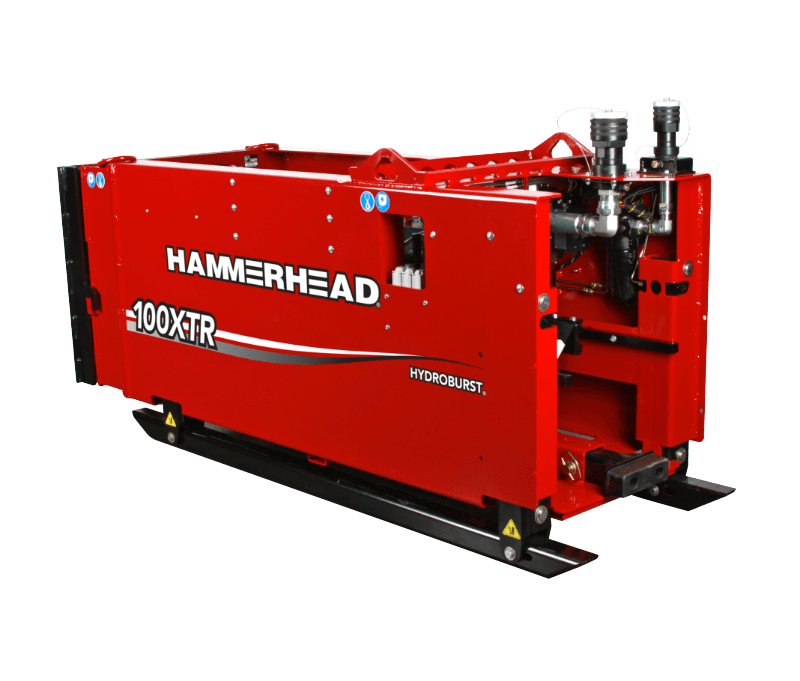

When it comes to trenchless repair and replacement of water and sewer underground infrastructures, we have it all. That’s ALL the equipment, consumables and services you need to get the job done. It’s engineered, made, and supported here in Wisconsin. So, why go anywhere else? HammerHead® Trenchless is your single source for rehab and replacement.