HammerHead® Brings Fast-Curing CIPP Technology to North America

HammerHead Trenchless, a Charles Machine Works Company, has announced its exclusive Bluelight™ LED system is now available in North America. Already proven in Europe and Russia, the Bluelight system is a Cured-In-Place Pipe (CIPP) lining system that cures up to five times faster than conventional methods. Made for laterals and small sewer pipes 4 to 10″ in diameter, this exclusive technology greatly reduces the time installers must wait for a liner to cure, allowing them to complete jobs more quickly.

“Without the Bluelight LED system, installers can waste hours waiting for a liner to cure,” said Matt Gabrielse, product manager of HammerHead Trenchless CIPP lines. “But our specially formulated resin cures with LED light, which is much quicker than traditional epoxy resins that are cured with steam, hot water or ambient air.”

While the curing speed alone helps installers complete more footage in a given workday, the Bluelight system’s LED technology offers another important advantage as well. Since the resin cannot be activated by heat, air or non-LED light sources, resin-impregnated liners are stable enough for storage and extended working times.

“The stability of the resin completely revolutionizes the CIPP process workflow,” Gabrielse noted. “Installers could wet out all the lining they require for next week’s jobs in the comfort and controlled environment of their own shop on a Friday afternoon.”

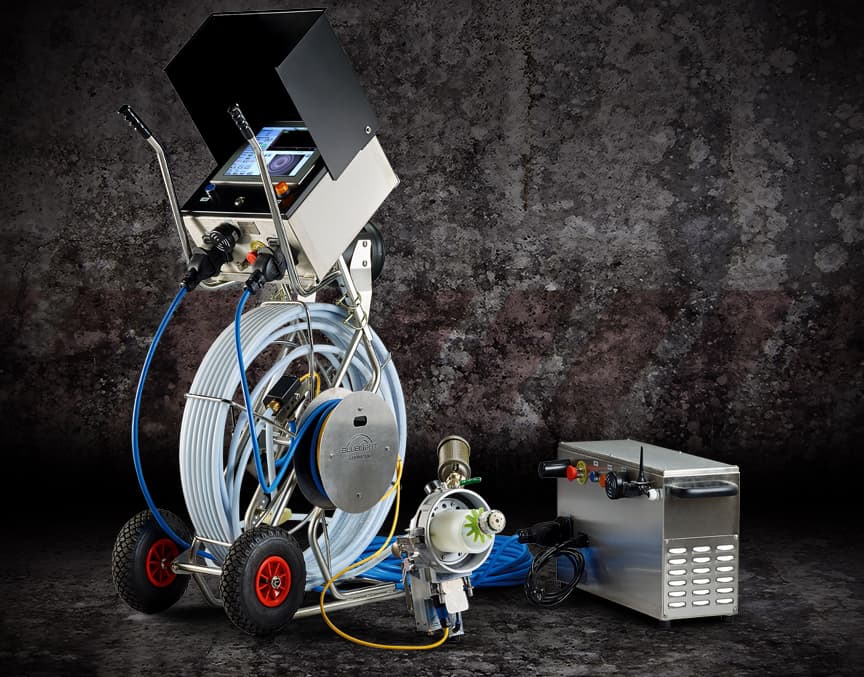

The Bluelight LED system is compact and lightweight, making it easily portable on the jobsite. In addition, it includes a camera mounted in the LED curing head, allowing the installer to visually inspect inverted lining and monitor the cure progression.

With testing and certifications now complete, the Bluelight LED CIPP lining system is exclusively available by direct sale from HammerHead throughout North America. It will be on display at the company’s booth (#5206) at the 2019 WWETT show in Indianapolis February 21-23.

About HammerHead Trenchless Click Here

About Charles Machine Works Click Here