Menu

Point repair solutions extend the life of damaged pipes

Overview

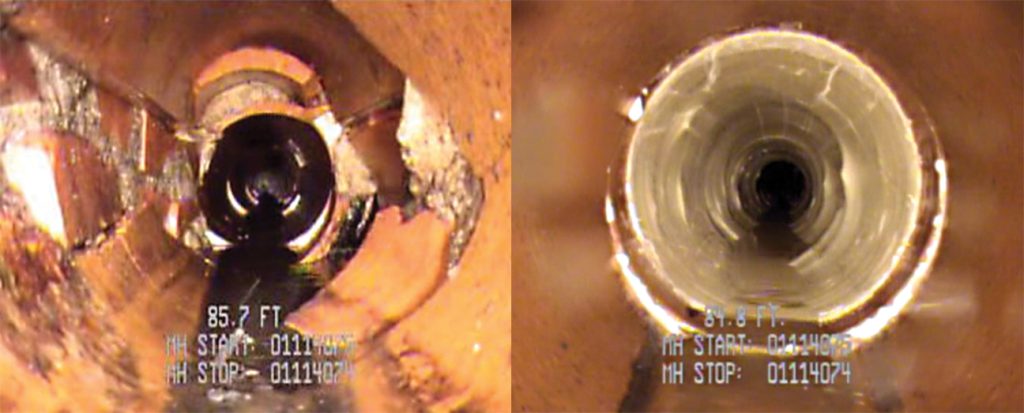

Point repair from HammerHead® Trenchless is an appropriate solution for a wide variety of issues seen in different types of pipes. It can be used in conjunction with CIPP installations or as stand-alone application over offset joints, pipe separations and damaged siphons. It can also be used to seal off interior drops and cap off unwanted laterals. It can even replace missing sections of pipe, repair 90° bends, bridge transitions or add extensions to a culvert.

Industries

Features

VERSATILE SOLUTION.

Point repair is an appropriate solution for a wide variety of issues seen in different types of pipes. It can be used in conjunction with CIPP installations or as stand-alone application over offset joints, pipe separations and damaged siphons. It can also be used to seal off interior drops and cap off unwanted laterals. It can even replace missing sections of pipe, repair 90° bends, bridge transitions or add extensions to a culvert.

CONVENIENT AND EFFICIENT

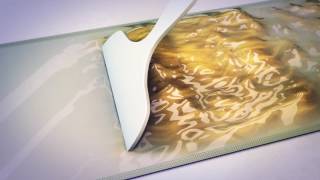

Point repair from HammerHead Trenchless is designed to be easy: easy to learn, easy to prepare & install, and easy to clean up. The simple installation process allows crews to quickly become confident and efficient. Plus, HammerHead offers on-the-job training to help ensure your crew’s success on every repair. Convenient packaging makes preparation and clean up hassle-free. While other point repair systems require you to apply messy resin with your hands, HammerHead point repair solutions are assembled to minimize time wasted on clean up. Resin is mixed in its purpose–made packaging, then spread with a spatula to saturate the mat. Each solution comes with a plastic working surface and gloves so clean up is as easy as folding up the plastic and throwing it in the trash.

LONGEST WORKING TIME, QUICK CURING TIME

The working time of HammerHead point repair systems is the longest of any silicate based resin offered by similar systems on the market. Choose between “winter” and “summer” point repair solutions to match working time to your job conditions.

NON HAZARDOUS, LONG SHELF LIFE

HammerHead point repair resin is odor-free, styrene-free and VOC-free. It presents no hazards to the environment or to human health. It keeps well in the container without the risk of leakage. Its long shelf life means you can keep inventory on site.

Custom Assembled System

Each point repair solution is custom-assembled to your project requirements and includes fiberglass mat, pre-measured resin and hardener, packer protection sleeves, spreading spatula, work surface, electricians’ tape, disposable gloves and ties. Materials are precisely cut, measured and weighed to eliminate waste and help ensure successful installations, every time.

Specifications

| Physical Properties | Test Method | Minimum Value |

|---|---|---|

| Flexural Modulas | ASTM D 790 | 1,200,000 psi |

| Flexural Strength | ASTM D 790 | 30,000 psi |