Menu

Bluelight LED CIPP Lining System

Work at Light Speed

Overview

The Bluelight LED CIPP lining system for laterals and small drain pipes is the most advanced light-curing system available. The innovative technology empowers CIPP lining pros by alleviating the time pressures of other CIPP systems. The specially formulated resin only cures under light in the “blue” wavelength, giving installers a significantly longer working time between liner wet-out and curing. Once installed, the automated curing system pulls the LED light head through the liner, curing the resin almost instantly — up to five times faster than other methods. Instead of waiting hours for the liner to cure, a 50-foot sewer line could be fully cured in under 12 minutes. With 500 systems in the field and millions of feet installed worldwide, the Bluelight LED lining system is a proven solution for lateral rehab.

Industries

Features

EXPANDED RANGE

Rehabilitate pipes 2” to 18” in diameter with the system’s 4 light head options.

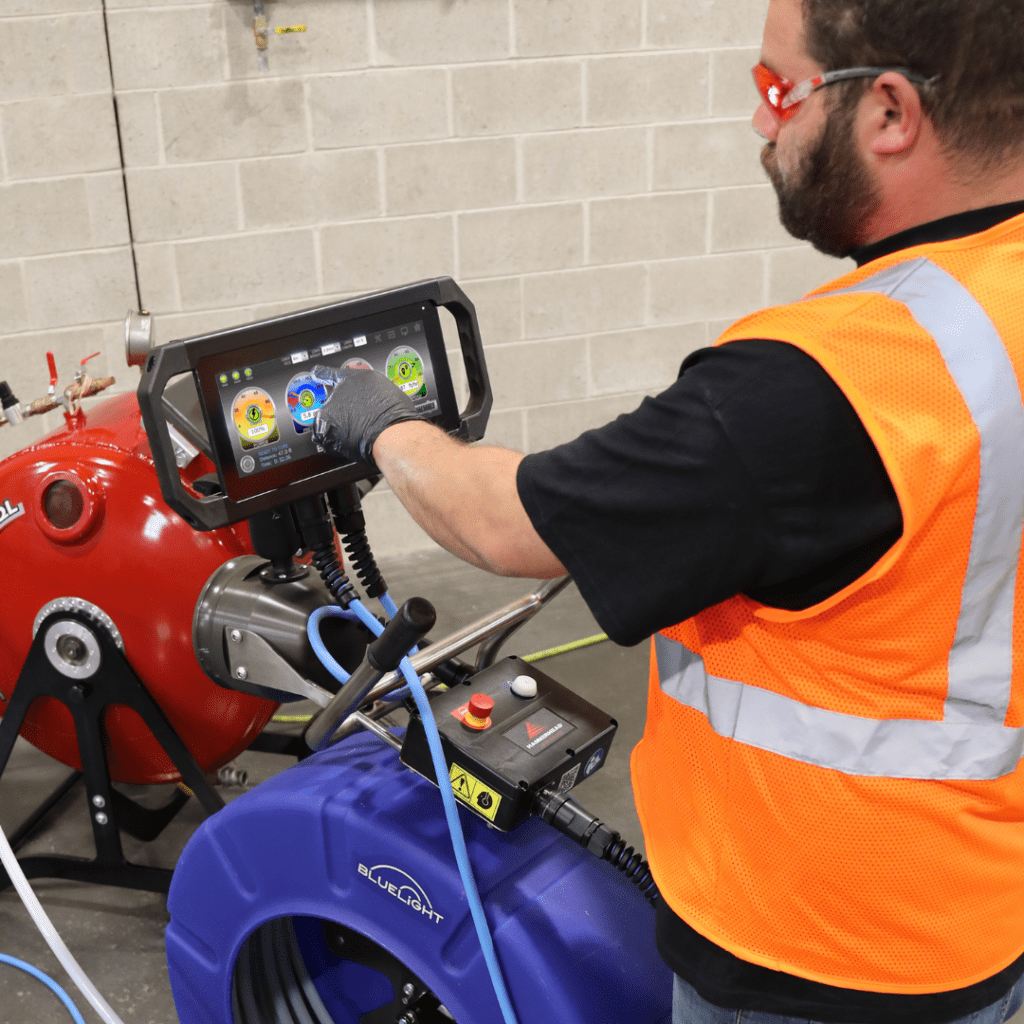

TOUCH SCREEN INTERFACE

The system features an intuitive touch-screen interface that is easy to learn and operate. Simply input the job specs and the system will automatically set pull-back speed.

INTERCHANGEABLE REELS

Ranging in lengths from 33 m to 100 m. Having more than one reel allows for more convenient transportation and keeps you in operation if one of the reels requires service.

SCREEN MOUNTING OPTIONS

The control unit can be rotated and repositioned letting the installer set it in their ideal viewing position.

MANEUVERABLE FRAME

The lightweight, ergonomic frame design makes the system more portable and easier to maneuver around cramped job sites.

LONG WORKING TIME

The Bluelight system resin only cures when exposed to “blue” light (444-457 nm) which gives installers extended working time, alleviating the time pressures of traditional curing methods.

AUTOMATED PULLBACK

The onboard computer controls pullback speed based on job parameters to fully cure the liner ensuring a quality result on every installation by reducing the potential for human error.

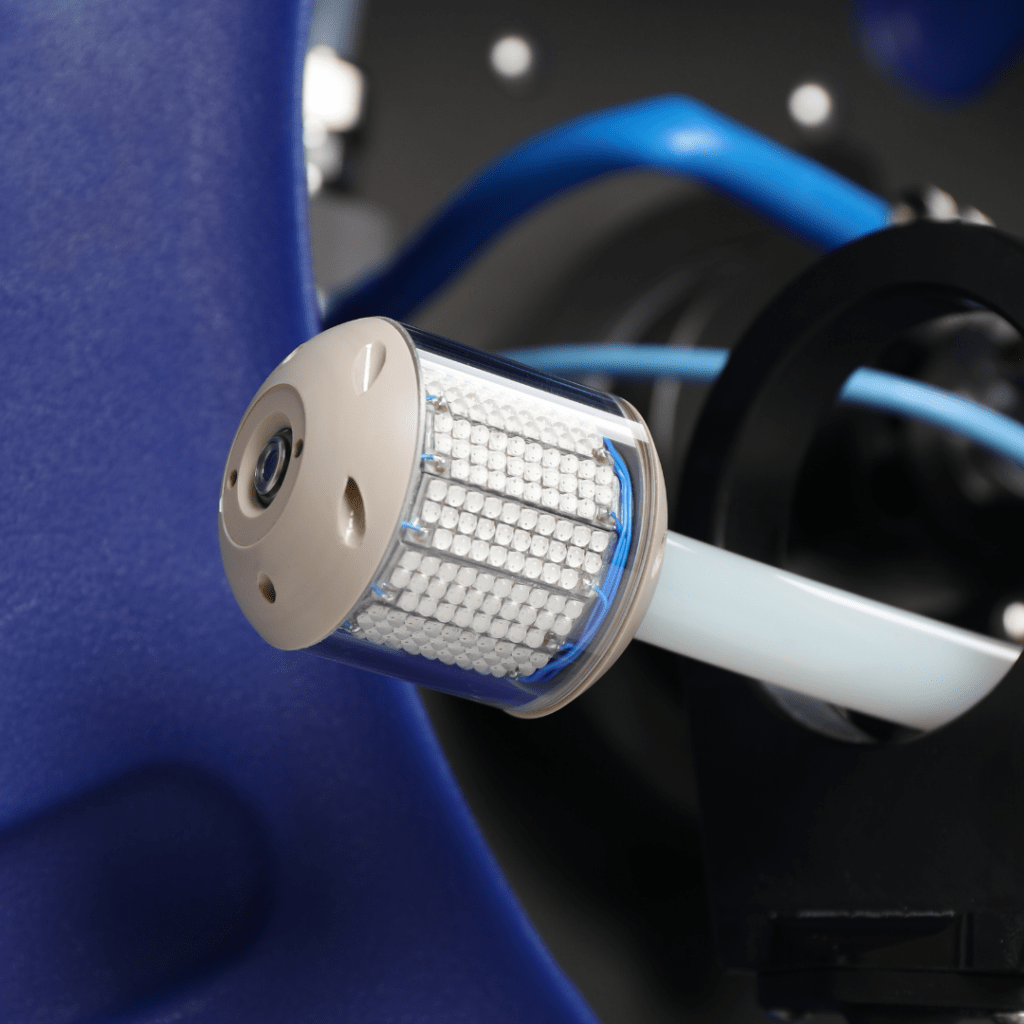

INTEGRATED CAMERA

Easily monitor the progress and quality of the installation with the camera integrated into the LED light head.