Menu

Products

HammerHead® Trenchless provides precision-manufactured equipment, comprehensive trenchless materials and supplies, and all the training and support you need to attack anything standing between you and renewed pipes.

Our Full Line of Products

Lateral CIPP

Learn MoreUsed in various gravity and pressure applications, our lateral lining systems help repair cracked or broken pipes, eliminate roots, complete missing pipe sections, and stop infiltration and exfiltration.

Main Line CIPP

Learn MoreOur cured-in-place pipe (CIPP) precision equipment supplies everything crews need to efficiently repair underground pipes, producing the best trenchless rehabilitation systems available in the market today.

Point Repair Kits

Learn MorePoint repair is a solution for a variety of issues seen in different types of pipes. It can be used in conjunction with CIPP installations or as a stand-alone application over offset joints, pipe separations, and damaged siphons, as well as used to seal off interior drops and cap off unwanted laterals.

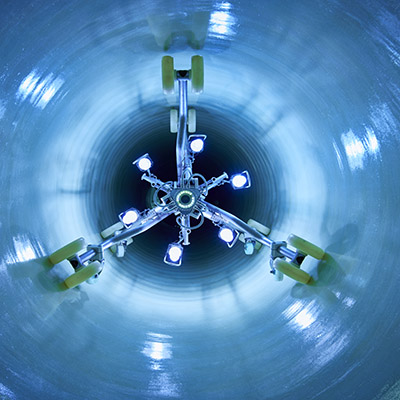

Reinstatement & Cleaning

Learn MoreFor small solutions and drain rehabilitation, our line of Picote products is used for pipe reinstatement, grinding chains for drain cleaning, and many other accessories.

Static Pipe Bursting Systems

Learn MorePipe bursting follows the path of the existing utilities, reducing utility strike risks and eliminating up to 85 percent of excavation work compared to open-cut methods.

Pneumatic Pipe Bursting Systems

Learn MorePneumatic pipe bursting systems are used by underground contractors as an effective method to replace failing, outdated or undersized sewer, water, and gas lines.

Pipe Slitting

Learn MoreThe configurable, flexible tooling string is pulled through the pipe, splitting it while simultaneously pulling in the new pipe in the existing path, minimizing risk to surrounding utilities.

Pipe Extraction

Learn MoreTrenchless pipe extraction is an innovative new method of replacing coated and bare steel gas service lines. Our new trenchless technology facilitates rapid replacement of at-risk steel gas pipes.

Hydroguide® Cable Winches

Learn MoreHydroGuide® cable winches are designed to maximize efficiency and minimize setup time. We offer three models of pulling power to handle a wide range of jobs.

Pipe Ramming

Learn MoreCompared to conventional methods, pipe ramming is used for placing steel casing under roads, railroads, finished landscapes, and structures. These products cut down on setup time and offer lower equipment and maintenance costs.

The Right Product for the Right Job

Contractors, consulting engineers, municipalities, and other underground construction professionals demand the best technology, equipment, and materials available to do the job right. Our line of innovative products helps solve trenchless challenges; operators’ nationwide benefit from cost savings and trenchless construction methods.

Training & Services

Part of the unsurpassed level of support HammerHead provides to customers comes from training and field service support. Our team of highly skilled application specialists have years of industry experience and are available for in-the-field training and application assistance. Additionally, our 5,000 sq. ft training facility is your direct link to product and application training, tailored to your business needs. Finally, our online learning platform fills the customer need for easy-to-access learning modules, available to you and your crew 24/7.